Time:2019.11.21 15:25 View: Anthor:admin

BackThe working principle of the boost converter

The general-purpose inverter is the principle of applying the frequency conversion technology and the micro-electronic technology. It is a power control device that controls the AC motor by changing the frequency of the working power of the motor. The principle is to convert the power frequency alternating current with constant voltage and frequency into alternating voltage with variable voltage or frequency. The working process is to first convert the power frequency AC power source into a DC power source through a rectifier, and then convert the DC power source into an AC power source whose frequency and voltage can be controlled to supply the motor.

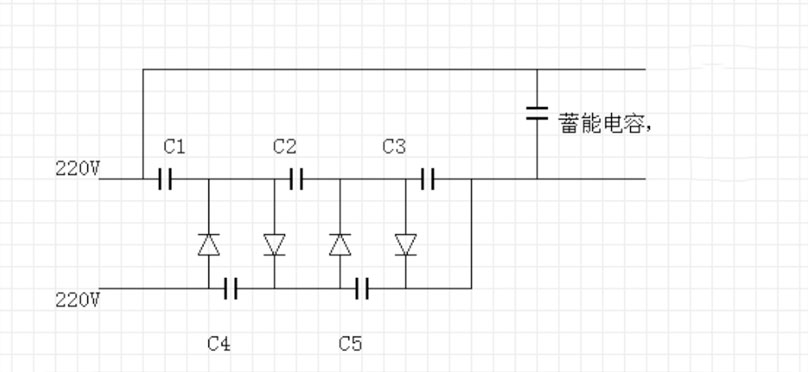

The booster converter converts the power frequency AC 220V power supply into a DC power supply through a rectifier (double voltage rectification) on the basis of the ordinary frequency converter, and then converts the DC power supply into a three-phase 380V AC power source whose frequency and voltage can be controlled. Supply the motor. This method does not boost through the transformer, but only boosts through the rectifier boost circuit, which greatly reduces the size and weight of the inverter. Compared to the voltage booster, the cost is lower.

The function of the boost inverter

1, single-phase to three-phase phase-shifting function, 220v to 380v boost function, frequency conversion function

2, with most of the functions of the general-purpose inverter, such as soft start function (reduced start current, reduce the impact on the grid, can replace the soft starter), speed control function (0 to motor rated speed stepless adjustment), terminal start and stop is positive Reverse switching function (control external motor to start, stop, forward and reverse, can replace AC contactor)

3, with motor protection function, over-current overload, over-voltage, over-temperature and short-circuit protection, etc., effectively extending the service life of equipment

The use of boost converter features

1. Ordinary civil power input, output fully matched three-phase asynchronous motor

2, according to civil single-phase electricity billing, good economy

3. Input wide-voltage range design, adapt to the working environment where the common mains voltage is low in some areas.

4, the output protection function is perfect, there are various protections such as overvoltage, overload, over temperature, short circuit, over current, etc.

5, some equipment can be used with sensors and PLC to achieve automatic control and energy saving purposes, such as temperature control fans, pumps, constant pressure water supply.

Compared with 220v to 380v voltage booster

1. The voltage booster has a built-in transformer coil, which is bulky and is several times larger than the same power boost converter. The mobile and transportation costs are extremely high;

2. When selecting the voltage booster, consider the motor starting current, the power must be at least twice the total power of the load, and further increase the cost, and the boost converter considers the overload condition, and the general load can be selected by a large power class;

3. The price of the same power voltage booster is twice or even three times that of the boost converter;

4. The voltage booster has no other additional functions and cannot be automatically controlled with other industrial computers. The additional functions of the boost converter can meet various complex industrial control occasions.

The actual problem that the boost converter can solve

1, the power supply voltage does not match the problem, that is, the power supply 220V, equipment power 380V

2, the power phase does not match the problem, that is, the power supply single phase, the equipment uses three-phase

3, the power frequency does not match the problem, that is, the power supply 50Hz/60Hz, the equipment power 0-650Hz (arbitrary setting)

The use of boost converter notes:

1. The input power supply of the boost inverter must be sufficient, otherwise it will fail to operate normally.

2. The booster inverter is boosted by the booster circuit. Suitable for the light load type of 22kw or less for load, in the selection, pay special attention to power selection, especially when the motor load is large.

3. The boost converter can only be used for inductive loads of motors, and cannot be used as other load power supplies.

4. The boost converter is not suitable for use in the field where fast start and stop are required, and in the case of potential load.

5. Some equipment motors can use three-phase 220V electricity by changing the motor connection. (If the motor star connection status is a three-phase 380V motor. Can be changed to a triangular connection, using three-phase 220 volts, please consult the motor manufacturer for details. ), at this time,it is recommended that you purchase our single-phase 220 volt to three-phase 220 volt inverter to solve the phase conversion problem.

Boost converter technical specifications

● Input and output characteristics

Input voltage range: 220V ± 15%

Input frequency range: 47 ~ 63Hz

Output voltage range: 0 ~ rated input voltage

Output frequency range: 0 ~ 650Hz

● Peripheral interface features

Programmable digital input: 4 inputs

Programmable analog input: AI1: 0 ~ 10V input, AI2: 0 ~ + 5V or panel potentiometer input Open collector output: 1 output

Relay output: 1 output

Analog output: 1 output, optional 4 ~ 20mA or 0 ~ 10V

● Technical performance characteristics

Control: PG-free vector control, V / F control

Overload capacity: 150% rated current 60s; 180% rated current 10s

Starting torque: without PG vector control: 0.5Hz / 150% (SVC)

Speed ratio: no PG vector control: 1: 100

Speed control accuracy: PG vector control: ± 0.5% of the maximum speed

Carrier frequency: 0.5k ~ 15.0kHz

● Features

Frequency setting mode: digital setting, analog setting, serial communication setting, multi-speed, PID setting.

PID control function

Multi-speed control function: 8-speed control

Swing frequency control function

Instantaneous power outage without stopping function

REV / JOG key function: user-defined multi-function shortcut keys

Automatic voltage adjustment function: When the grid voltage changes, the output voltage can be automatically maintained constant

Provide up to 25 kinds of fault protection: over-current, over voltage, under voltage, over temperature, phase loss, overload and other protection.

Address: 7F Bldg #E, North Area No. 8 Shangxue Technology Industrial city,Shenzhen,China

Company email: szqinverter@foxmail.com

My WhatsApp: +86 13923476670

copyright ©深圳市玮肯电气技术有限公司 版权所有 粤ICP备13028075号-3

Web Map 丨